Ultrasonic Watertight Testing: Precision, Reliability, and Assurance Ensuring Watertight Integrity with Cutting-Edge Technology

In industries where watertight integrity is crucial—such as aerospace, automotive, marine, and construction—reliability and precision are paramount. Our ultrasonic watertight testing services offer a non-destructive and highly accurate method for assessing and ensuring the water tightness of components and structures.

What is Ultrasonic Watertight Testing?

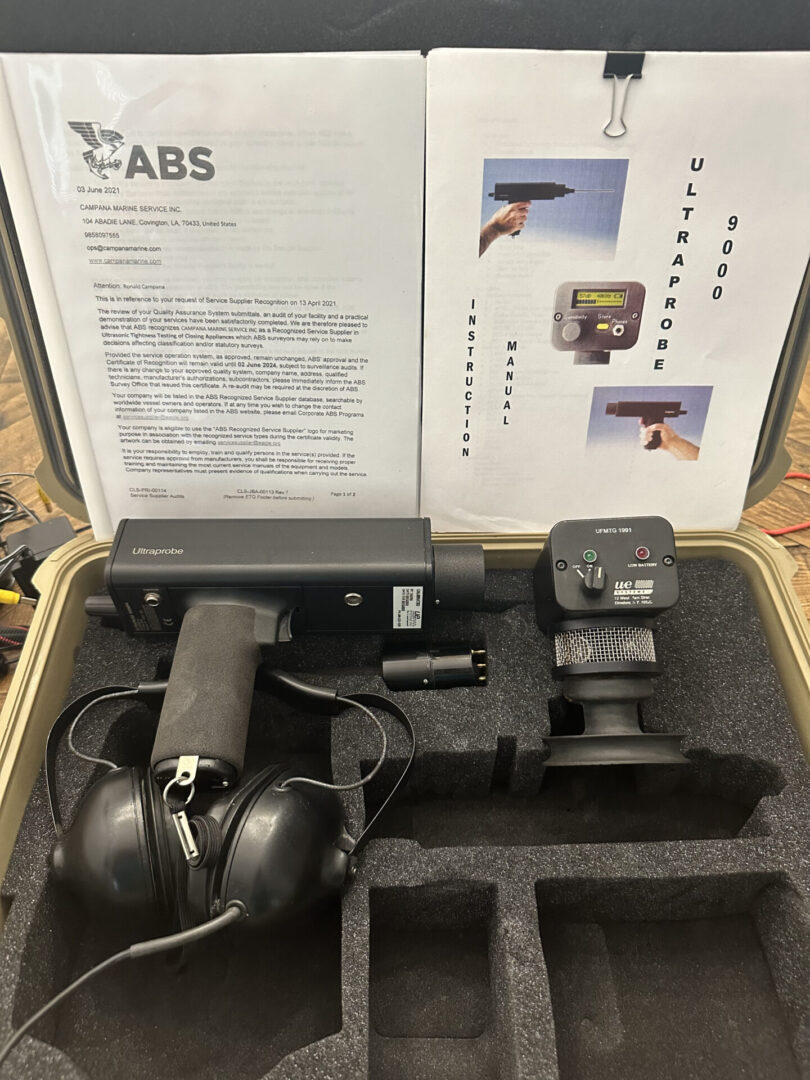

Ultrasonic watertight testing uses high-frequency sound waves to detect and evaluate potential leaks and weaknesses in materials and structures. By sending ultrasonic pulses through a medium and measuring the reflected signals, we can identify flaws, inconsistencies, and areas of concern with exceptional accuracy.

Key Benefits of Ultrasonic Watertight Testing

How It Works

Why Choose Us?

Applications

Get in Touch

Ensure the reliability and durability of your components with our precise ultrasonic watertight testing services. Contact us today to learn more about how we can assist you in maintaining the highest standards of quality and safety.